Generator Preventive Maintenance from WPP: Extend the Life of Your Power Equipment

A well-planned, regularly scheduled preventive maintenance (PM) program is essential to ensuring reliability in power generation equipment. A proactive approach also minimizes downtime, as operators can arrange to have backup power while the primary unit is being serviced.

Worldwide Power Products offers preventive maintenance for all major brands, models, and sizes of generators, whether diesel or natural gas, standby or prime power.

Our service coverage extends outward from our facilities in Northwest Houston throughout the Texas Gulf Coast region.

Our preventive maintenance inspections cover 78 points across the following areas:

- engine lubricating system

- engine cooling system

- engine air intake system

- engine exhaust system

- engine fuel system

- engine electrical system

- other engine related systems

- generator and distribution system

- generator running inspection

- departure inspection.

Benefits of Preventive Maintenance

Prevent damage

to equipment caused by deferred maintenance

Minimize loss

of revenue due to unplanned downtime

Save money

by avoiding costly repairs

Stay compliant

with regulations*

*Visit our pages on regulatory compliance to learn more:

How Our Maintenance Program Works

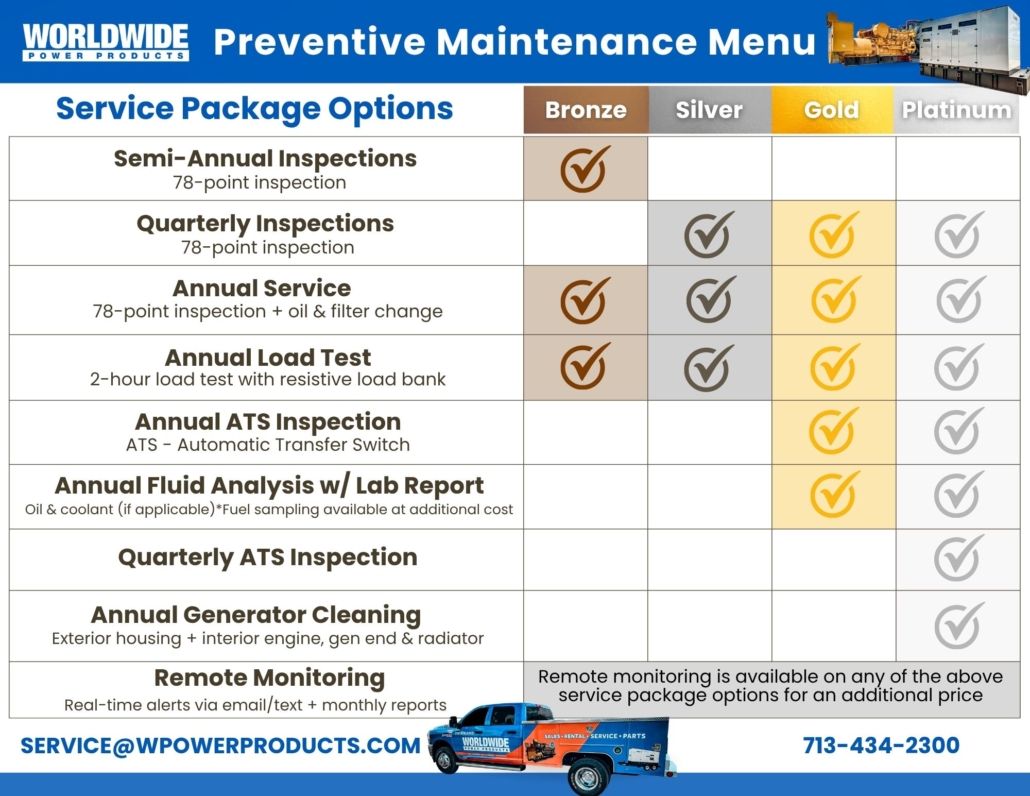

We tailor the preventive maintenance process to your operations—whether you need minimal or frequent visits, we align with your schedule to reduce disruption.

- Consultation: We start with a conversation—on-site or remotely—to understand your facility’s power demands, maintenance history, regulatory requirements, and uptime priorities.

- Strategy: We work with you to craft a maintenance plan that fits your requirements.

- Service: Our technicians perform the work around your schedule to minimize disruption to your daily operations.

- Support: We continue monitoring your maintenance schedule, reaching out when it’s time to arrange a tune-up and advising you of any specific work that may be needed in the future.

Load Bank Testing

Load bank testing is a critical part of preventive maintenance that verifies your generator can perform reliably under real-world electrical loads. Rather than waiting for a power outage to discover performance issues, this controlled test safely simulates full-load conditions to uncover hidden problems such as overheating, fuel system weaknesses, or battery failures.

WPP offers load bank testing as part of its PM program but also as a standalone service to customers wishing to have their own power generation equipment tested on demand, either in the field or at our location.

In NFPA 110, the National Fire Protection Association has established the standards for monthly maintenance and operation for standby generators: “Generators should be exercised monthly at 30% of the nameplate rating or loaded to the minimum engine exhaust temperature recommended by the engine manufacturer.”

Additional benefits of load bank testing include:

- Reducing wet stacking problems

- Critical exercising of standby generator sets

- Ensuring proper installation and load transfer

- Load optimization

Fuel Polishing, Management & Analysis

The National Fire Protection Agency (NFPA) recommends that “diesel fuel be tested for degradation no less than twice annually with a maximum of 6 months between testing at least once per year.”

WPP offers diesel fuel sampling to catch contamination issues before they impact reliability. During scheduled maintenance visits, WPP can also refuel or top off your diesel tanks with high-quality fuel. We also offer optional fuel analysis, sampling and treatment for contamination as an optional service with each visit.

DIY Tips for Preventive Maintenance in Any Season

Cold weather can make it challenging for generators to start and perform if the equipment is not properly maintained. Check out our maintenance tips to prepare your generator for winter and help ensure your equipment is ready to run when you need it.

Heat can be problematic as well. Take a look at our tips for safeguarding your standby or continuous generator during extreme heat to guarantee that performance is not affected by high temps.

Why Leading Facilities Choose WPP for Preventive Maintenance

Our services division receives training directly from OEMs in best practices for maintaining their products. Moreover, we have our own technician training program–unique in the power generation services industry–that includes training in relevant regulations and helps ensure WPP preventive maintenance is among the most comprehensive in the industry.

Also, when you use us for your PM, it’s simple to arrange backup power for the duration of service by renting from our rental department.

We have an extensive inventory of diesel and natural gas gensets and accessories to cover any application.

Generator Preventive Maintenance FAQs

How often should a generator be serviced?

All generators should have a quarterly inspection, and at one of those inspections the fuel and oil filters should be changed. Load banking the generator should be done annually regardless of use. For generators used for extended run times throughout the year, additional service visits are necessary.

Reference the OEM-suggested interval for oil changes. For example, if your unit requires a 250-hour service interval, every 10 days of continuous operation a service is required.

What generator manufacturers can WPP service?

We can service all major brands of generators, including Caterpillar, Cummins, Generac, Kohler, Detroit Diesel, and MTU.

Do you provide generator rentals during maintenance?

Yes! Talk to our rental department about renting a unit during your next maintenance visit.

Do you offer 24/7 emergency support?

Support from our experienced technicians is available 24/7/365.

Get Generator & Engine Service—Fast, Reliable, 24/7

Complete this quick form and our Houston-based team will respond within 24 hours.